We honor their memory by doing SAFETY better and differently!

April 28th was Workers’ Memorial Day. This was a time to reflect on all those who have lost their lives or were seriously injured at work. This was a time to honor their memories and the suffering of their families.

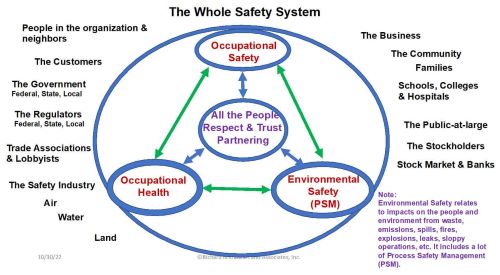

The Bureau of Labor Statistics reports about 5,200 deaths and 2,300,000 serious injuries in each of the last 6-7 years. The AFL-CIO’s 2023 “Death on the Job” report estimates that occupational diseases kill 120,000 people each year. Not only is this bad for the people and their families, it is also bad for the businesses. These injuries cost businesses far more than the work that can be done to prevent most of them.

It seems that for many companies, the dash for profits is their primary goal, and it must be achieved regardless of the adverse impact on the workers. I don’t know why the financial losses seem to be ignored by the businesses.

OSHA is taking a stronger stance and is increasing the fines and penalties for violations. The EPA is also more involved through their initiative titled Reducing Risks of Accidental Releases at Industrial Facilities.

The EPA participated in a recent court decision against the DuPont LaPorte, TX Plant where four people were killed on November 15, 2014. The decision resulted in:

- $12,000,000 penalty,

- $4,000,000 Community Service payment to the National Fish and Wildlife foundation to help to restore the western shore of Galveston Bay, and

- One-year probation for the Unit Operations Manager.

There is a far simpler, easier, and less expensive way to quickly reduce the number of deaths, injuries, illnesses, and uncontrolled releases.

No one can claim that they do not know how to vastly reduce incidents, injuries, fatalities, and wastes to the environment. Over the last 35 years, I have helped a number of organizations cut these rates by over 90% quickly. When I was the Plant Manager at the big DuPont Chemical Plant in Belle, WV, in the early 1990’s, we cut injury rates by about 97%, wastes dropped by 95%, and earnings went up about 300% in just 4 years. I have also published several articles in the ASSP journal, Professional Safety, which prove we can do a lot better in reducing the number of deaths, injuries, and illnesses at work.

I don’t work on reducing the safety and environmental releases numbers, they are just an outcome that is useful in seeing if the work is accomplishing its goal of having everyone go home healthy and injury free, and we are not hurting the environment.

Building the Capacity of the People

The focus of my work is building the capacity of the people to:

- be together

- think together

- listen and learn together

- solve problems together

- make decisions about their work and act together, and finally

- reflect on what they are learning, make improvements and co-create their future together

The managers and safety leaders can make this happen by doing just three things, every day:

- Go into your workplace, be among the people, sit with them and talk with them about things like:

- the safety problems they are running into

- what is holding them back

- what are the challenges they face every day

- how you can help them to solve their problems

- how the business is doing

- what the competition is doing

- how their family is doing

- what activities are their kids are involved in like baseball

- etc.

- Help to build trust by talking respectfully with the people in their workplaces, listening and learning about their challenges and contributions.

- Give them credit for their good work and help them see how their work helps the business and builds the long run sustainability.

I walked among the people every day for 5 hours a day (the plant was quite large) for almost 8 years. I did not make decisions there; I listened, watched, and learned how to help the people to build capacity and achieve excellence. I stayed in integrity with them – creating meaning, behaving with honesty and reliability, and caring for ourselves and others. We built a culture of trust where we could all learn and grow. Some managers have told me that this was a waste of time, and they have other, more important work to do. Really? I have not talked with any manager who got the improved safety, environmental, productivity and earnings improvements we achieved at the Belle Plant.

This is simple work which requires the will and courage to be in the process and do it. By helping each other, we can all do this important work!