As I talk with Leaders, I often hear that things are so entrenched they cannot even conceive that this type of “betterment” can happen for them.

We know that it can, and we prove it over and over again, as we work with leaders, their teams, and their businesses.

We know that it can, and we prove it over and over again, as we work with leaders, their teams, and their businesses.

CULTURE: We help to knock down the walls that have grown up between people and groups so that the arguments and fighting stop and they learn to value and help each other. We help to drill holes in the silos of production, HR, maintenance and finance so that people can talk to each other to get the information they need to do their jobs. We help to remove the barriers that are restricting the up and down flow of critical information, improving its accuracy, so the organization can function more easily. We help to remove the barriers between the people writing rules and procedures (the work- as-imagined) and those doing the front-line work (the work-as-done). We help people to see that most of the injuries and incidents are the result of patterns and processes that need improvement and shift away from a culture of blame and criticism.

SAFETY: I believe that we do not have a right to make our living in a place where it is okay to hurt people. When we make this our top belief, many fewer people get hurt and our economic performance is a lot better as well. As we learn to work this way the barriers and roadblocks melt away and new channels and connections emerge.

LOSS: Avoiding the losses and waste means that our businesses are more competitive and healthy. How much do you suppose an OSHA Lost Time Injury costs the business?

- The pain and suffering is miserable.

- There is the direct cost of the doctors, hospitals, medications, etc.

- We loose time:

- having to investigate the injury and incident.,

- writing reports,

- having an OSHA investigation,

- perhaps the cost of challenging OSHA’s findings,

- legal costs for the company attorneys,

- preparing for a potential law suit,

- the cost of lost production time,

- the cost of bringing someone and train them to replace the injured person,

- the cost of lost sales,

- the cost of bad publicity,

- the cost of lower morale among the people,

- and so on.

BOTTOM LINE: When the safety gets right, everything else gets right as well. In this more positive culture, not only does the waste of injuries and incidents go away, people shift the way that they chose to work together resulting in other improvements like:

- fewer arguments,

- fewer grievances,

- better meetings,

- fewer meetings,

- more suggestions for improving our systems and processes,

- people taking the lead in helping to fix something that is not right,

- new ideas for better customer service emerge,

- lean manufacturing works better,

- the quality of products and services get better,

- absenteeism drops, and

- people can work together to build a better future.

When the safety performance and culture get better, the organization thrives.

These are things that each organization can work on right now. In Partner-Centered Leadership, Richard N. Knowles & Associates can help organizations to achieve all these things. This does not require investment.

- Get clear on your thinking and purpose.

- Go into your organization talking with and listening to the people.

- Help them to build on their ideas.

- Let them know how important they are to the success of the business.

- Do this with respect and honesty.

Excellent firms don’t believe in excellence – only in constant improvement and constant change.

~ Tom Peters

Our new year is full of opportunities, dark clouds and unknowns. The world is full of strife of all sorts. Our political situation here in the U.S. is full of hope, tension, noise, and unknowns. So many people are screaming about their opinions that it is almost impossible to hear. I get so tired of it that I often just quit trying to listen. That is probably a mistake for me to do that; we are all connected and I can’t just go away and hide. None of us can do that.

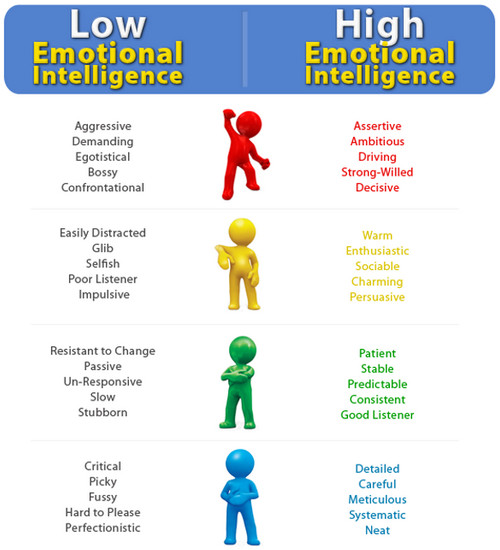

Our new year is full of opportunities, dark clouds and unknowns. The world is full of strife of all sorts. Our political situation here in the U.S. is full of hope, tension, noise, and unknowns. So many people are screaming about their opinions that it is almost impossible to hear. I get so tired of it that I often just quit trying to listen. That is probably a mistake for me to do that; we are all connected and I can’t just go away and hide. None of us can do that. As we bring this sort of thinking and being together into our workplaces, we can seek ways to improve our safety performance and business results. I have found over and over that we can vastly improve our safety and business performance when we share information together, listen for understanding, develop trust among us and see how well are all contributing, solutions emerge. When we help to change the behavior of bullies of get them out of the work place, we get even better.

As we bring this sort of thinking and being together into our workplaces, we can seek ways to improve our safety performance and business results. I have found over and over that we can vastly improve our safety and business performance when we share information together, listen for understanding, develop trust among us and see how well are all contributing, solutions emerge. When we help to change the behavior of bullies of get them out of the work place, we get even better.

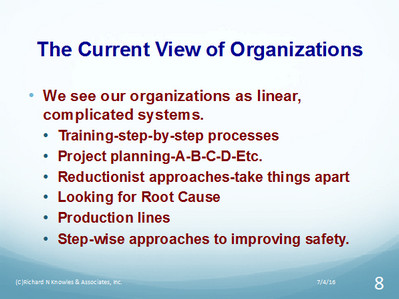

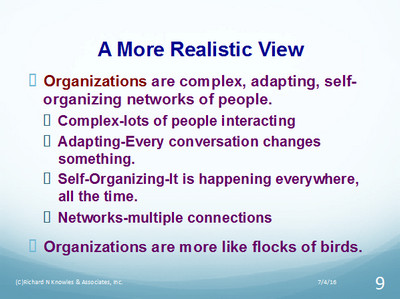

As this year comes to an end, we will be looking at our overall performance to see how we did and to plan for 2017. We will usually look at our injury statistics like the total recordable injury rate and try to determine how we performed. Often quite independently, others will look at other performance indicators to see how they came out. We act as if these are independent of each other, but in our organizations everything is connected so all aspects of performance influence each other. Everything happens through the people. All the parts are interconnected. Excellence in safety performance is strongly related to our total performance because it all works through the will of the people.

As this year comes to an end, we will be looking at our overall performance to see how we did and to plan for 2017. We will usually look at our injury statistics like the total recordable injury rate and try to determine how we performed. Often quite independently, others will look at other performance indicators to see how they came out. We act as if these are independent of each other, but in our organizations everything is connected so all aspects of performance influence each other. Everything happens through the people. All the parts are interconnected. Excellence in safety performance is strongly related to our total performance because it all works through the will of the people. Work-as-imagined and work-as-done are ideas developed by Erik Hollnagel in his book, Safety-I and Safety-II (2014. Ashgate Publishing Ltd., UK). Safety I is our traditional top-down management approach to safety management where rules and procedures are issued by those far from the actual work. This is like the approach discussed in the proceeding paragraph. I think that a lot of people are trying to do good safety work from the Safety I perspective, but the results are not improving fast enough.

Work-as-imagined and work-as-done are ideas developed by Erik Hollnagel in his book, Safety-I and Safety-II (2014. Ashgate Publishing Ltd., UK). Safety I is our traditional top-down management approach to safety management where rules and procedures are issued by those far from the actual work. This is like the approach discussed in the proceeding paragraph. I think that a lot of people are trying to do good safety work from the Safety I perspective, but the results are not improving fast enough. A recent article in the October 13, 2016

A recent article in the October 13, 2016  This story illustrates so many of the changing conditions and people involved in our work places. Most of our companies do a good job in risk assessments and developing safe working procedures. However, this planning often takes place away from the actual location where the work will be done. This is sometimes called the “blunt end” of the safety process where the people doing the planning do not understand what happens in the work at “sharp-end” where conditions and demands may be quite different, and where most of the injuries happen.

This story illustrates so many of the changing conditions and people involved in our work places. Most of our companies do a good job in risk assessments and developing safe working procedures. However, this planning often takes place away from the actual location where the work will be done. This is sometimes called the “blunt end” of the safety process where the people doing the planning do not understand what happens in the work at “sharp-end” where conditions and demands may be quite different, and where most of the injuries happen. Consider the Golden Gate Suspension Bridge (San Francisco) built between 1933 and 1937, an architectural marvel, thought to be impossible because in order to bridge that 6,700 ft. strait, in the middle of the bay channel, against strong tides, fierce winds, and thick fog, meant overcoming almost impossible odds. But it was built, with a grand opening in May of 1937, deemed, at the time of its completion, to be the tallest suspension bridge in the world as well as the longest. A man named Joseph Strauss engineered many new ideas, including developing safety devices such as movable netting, which saved 19 lives; though in all, there were 11 men lost during this construction. Thousands of men – workers of varying ages and from varied ethnic groups – came together to complete this project. (They had to listen and learn to be successful together.)

Consider the Golden Gate Suspension Bridge (San Francisco) built between 1933 and 1937, an architectural marvel, thought to be impossible because in order to bridge that 6,700 ft. strait, in the middle of the bay channel, against strong tides, fierce winds, and thick fog, meant overcoming almost impossible odds. But it was built, with a grand opening in May of 1937, deemed, at the time of its completion, to be the tallest suspension bridge in the world as well as the longest. A man named Joseph Strauss engineered many new ideas, including developing safety devices such as movable netting, which saved 19 lives; though in all, there were 11 men lost during this construction. Thousands of men – workers of varying ages and from varied ethnic groups – came together to complete this project. (They had to listen and learn to be successful together.) Consider the feat of building the monumental Hoover Dam (1931-1936) – a miracle of technology and engineering. No dam project of this scale had ever been attempted before. There were 21,000 people working at that site with approximately 100 industrial deaths. The walls for this structure – that would uphold the weight of the dam – required workers called “high-scalers” who excavated the cliffs, dangling on ropes from the rim of the canyon. Can you even fathom this?

Consider the feat of building the monumental Hoover Dam (1931-1936) – a miracle of technology and engineering. No dam project of this scale had ever been attempted before. There were 21,000 people working at that site with approximately 100 industrial deaths. The walls for this structure – that would uphold the weight of the dam – required workers called “high-scalers” who excavated the cliffs, dangling on ropes from the rim of the canyon. Can you even fathom this? Consider the great Niagara Power Project (1957-1961). During construction, over 12 million cubic yards of rock were excavated. A total of 20 workers died. When it opened in 1961, it was the Western world’s largest hydropower facility. Many people, including from the “greatest generation” and the “traditionalist generation,” worked together on this project. It was a 24/7, multi-year project.

Consider the great Niagara Power Project (1957-1961). During construction, over 12 million cubic yards of rock were excavated. A total of 20 workers died. When it opened in 1961, it was the Western world’s largest hydropower facility. Many people, including from the “greatest generation” and the “traditionalist generation,” worked together on this project. It was a 24/7, multi-year project. In many of our newsletters, I have talked about helping organizations co-create their safety future using the

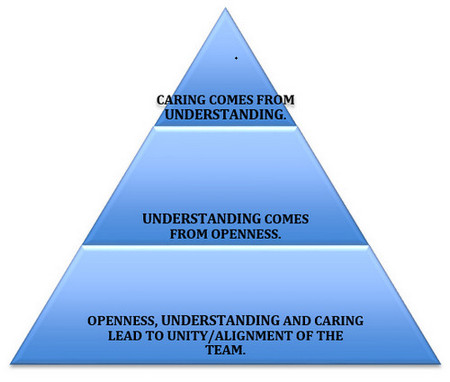

In many of our newsletters, I have talked about helping organizations co-create their safety future using the  In my June 29th presentation at the American Society of Safety Engineers 2016 Professional Development Conference, I discussed the fact that one of the best ways for the safety professional attending the talk to help to improve the safety performance in their workplaces was to show the people that they cared about them and to enable them to make decisions about their specific work. I want to elaborate on these ideas in this newsletter. This is not just for the safety professional. This is for every team leader, supervisor, and workgroup leader. Going into your workplaces and opening up the conversations is a journey; each time you do this it gets easier and more effective. (Caring, Understanding and Openness!)

In my June 29th presentation at the American Society of Safety Engineers 2016 Professional Development Conference, I discussed the fact that one of the best ways for the safety professional attending the talk to help to improve the safety performance in their workplaces was to show the people that they cared about them and to enable them to make decisions about their specific work. I want to elaborate on these ideas in this newsletter. This is not just for the safety professional. This is for every team leader, supervisor, and workgroup leader. Going into your workplaces and opening up the conversations is a journey; each time you do this it gets easier and more effective. (Caring, Understanding and Openness!) Eighty (80) pages and counting…that’s how far I got while perusing the numerous pages for the 2015 fatalities logged on OSHA reports – there were still many names and circumstances yet to read.

Eighty (80) pages and counting…that’s how far I got while perusing the numerous pages for the 2015 fatalities logged on OSHA reports – there were still many names and circumstances yet to read.