A 19-Year Case Study

On Tuesday, August 18, 2020, from 4:15 to 4:45 PM, I will be making a virtual presentation at the AiCHE 16th Global Congress on Process Safety. The paper is a 19-year case study demonstrating a successful plant leadership transition that improved process safety performance.

When I was transferred to the DuPont Belle, West Virginia plant in 1987, the Total Recordable Injury Case Rate (TRC) was about 5.8 and emissions to air, water and ground, as reported in the EPA Toxic Release Inventory (TRI) annual report, was over 6,000,000 pounds/year. Within three years, both of these had dropped by about 95% to a TRC of about 0.3 and a TRI of about 275,000 pounds/year. Emissions to the environment is one way to measure how well the process safety is working; the better the process safety work, the lower the emissions to the environment.

When I was transferred to the DuPont Belle, West Virginia plant in 1987, the Total Recordable Injury Case Rate (TRC) was about 5.8 and emissions to air, water and ground, as reported in the EPA Toxic Release Inventory (TRI) annual report, was over 6,000,000 pounds/year. Within three years, both of these had dropped by about 95% to a TRC of about 0.3 and a TRI of about 275,000 pounds/year. Emissions to the environment is one way to measure how well the process safety is working; the better the process safety work, the lower the emissions to the environment.

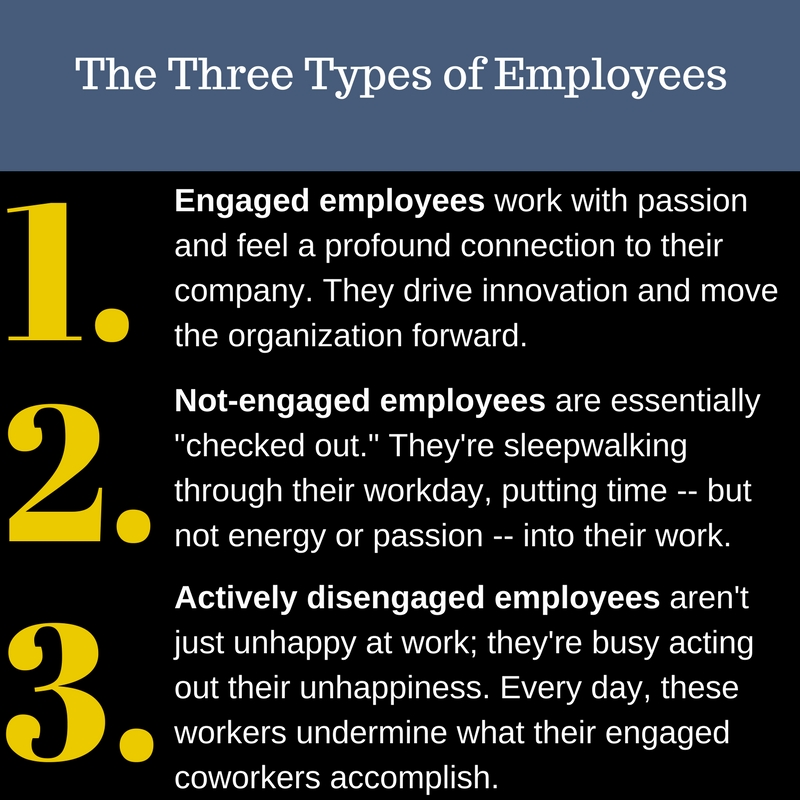

I was using a highly, participative leadership process I called Partner-Centered Leadership for Occupational Injuries and Health, as well as for Process Safety; this was a highly integrated process with just about everyone involved, and consciously working together to make our plant safer and have less impact on the environment. When I was transferred by DuPont in 1995 and replaced by a traditional plant manager using a top-down driven management process, things changed.

The process safety work was pulled away from the occupational safety and health effort and taken over by the managers. The occupational safety and health work continued to be led by the first and second level supervisors using the Partner-Centered Leadership approach. The highly participative leadership approach and the top-down management approach were running in parallel (the same business conditions, the same regulatory pressures, the same people, the same community). The occupational safety and health performance stayed at a rate of 0.3 or better for the next 15 years.

But the five different plant managers who came in during that period gradually cut back the process safety management resources and effort. They cut back on the manpower, allowed work-orders to pile up, stretched out the inspection intervals, ignored feedback from the operators and mechanics about the deteriorating conditions, etc. The TRI emissions rose by about ten-fold to over 2,500,000 pounds/year.

The process safety management collapsed in January of 2010 with major, accidental releases to the air and river and they had a man get killed with a phosgene release. When the US Chemical Safety Board investigated in late 2010, they reported that while the occupational safety and health performance was the best in the DuPont Company, the process safety management had fallen apart and the plant was not even using the DuPont standard procedures. This was a sad commentary about how far things had fallen.

The process safety management collapsed in January of 2010 with major, accidental releases to the air and river and they had a man get killed with a phosgene release. When the US Chemical Safety Board investigated in late 2010, they reported that while the occupational safety and health performance was the best in the DuPont Company, the process safety management had fallen apart and the plant was not even using the DuPont standard procedures. This was a sad commentary about how far things had fallen.

This 19-year case study clearly shows that a highly participative leadership process produces much better results that the top-down management process.

An Online Course Offering

Beginning August 24th, I will be presenting a six-week course on Leadership and Using the Process Enneagram©. The Process Enneagram© was a key leadership tool I used when I was at Belle. I have used this tool successfully around the world with people in all sorts of organizations and businesses in the 25 years since I retired from DuPont. Wherever I have used it in my consulting, safety and total performance has improved.

This Online course is the first in a series to teach about leading and using the Process Enneagram©.

Our businesses, our schools and hospitals, our governments, and not-for-profits, at all levels, are fractured and coming apart. Change is coming faster and faster. So many people seem to be trying to cope by pulling into their shells and trying to push the turmoil all away. The trust levels among all the various groups is very low. So many loud voices are pushing their version of the “truth” that it is almost impossible to tell who is being honest and should be listened to. How do we find the truth?

Our businesses, our schools and hospitals, our governments, and not-for-profits, at all levels, are fractured and coming apart. Change is coming faster and faster. So many people seem to be trying to cope by pulling into their shells and trying to push the turmoil all away. The trust levels among all the various groups is very low. So many loud voices are pushing their version of the “truth” that it is almost impossible to tell who is being honest and should be listened to. How do we find the truth? In thinking about your own place of work, what do you suppose it would be like if people did some of the things mentioned earlier in this newsletter? Do you think that you could begin talking with others about building a more respectful environment? What do you think it would be like if you could openly talk together about the important issues like improving the safety of your job? What would it be like if the managers and supervisors talked frequently about with everyone about how the business was doing the challenges from the competition? What would it be like if you knew that someone was looking out for your back? What would it be like if you felt you were in an environment of trust? What would it be like if people really asked important questions and talked about them? What would it be like if people in upper management asked you for your honest opinion and really listened? That’s called breaking the iceberg and engaging in authentic conversations!

In thinking about your own place of work, what do you suppose it would be like if people did some of the things mentioned earlier in this newsletter? Do you think that you could begin talking with others about building a more respectful environment? What do you think it would be like if you could openly talk together about the important issues like improving the safety of your job? What would it be like if the managers and supervisors talked frequently about with everyone about how the business was doing the challenges from the competition? What would it be like if you knew that someone was looking out for your back? What would it be like if you felt you were in an environment of trust? What would it be like if people really asked important questions and talked about them? What would it be like if people in upper management asked you for your honest opinion and really listened? That’s called breaking the iceberg and engaging in authentic conversations! I feel we are not moving fast enough to get to higher levels of performance. Way too many people are getting hurt and killed. Safety is a part of all we are doing and the whole system needs to be making improvements.

I feel we are not moving fast enough to get to higher levels of performance. Way too many people are getting hurt and killed. Safety is a part of all we are doing and the whole system needs to be making improvements. I was given the opportunity to talk about my work on Partner-Centered Leadership and shared information about the Process Enneagram, which is such a powerful tool to help people to come together to solve their complex problems. Partner-Centered Leadership is focused on sharing information, building trust and interdependence, helping everyone see the importance of their work for the success of the whole enterprise and moving into a better future. Everyone at the workshop was seeking ways to actually move into Safety II and make it happen so there was a lot of interest in this work.

I was given the opportunity to talk about my work on Partner-Centered Leadership and shared information about the Process Enneagram, which is such a powerful tool to help people to come together to solve their complex problems. Partner-Centered Leadership is focused on sharing information, building trust and interdependence, helping everyone see the importance of their work for the success of the whole enterprise and moving into a better future. Everyone at the workshop was seeking ways to actually move into Safety II and make it happen so there was a lot of interest in this work. Leaders are people who have a vision of what is possible, are concerned and care enough to make a difference, have the courage and commitment to do the work, and truly engage with people to learn, grow and to achieve their results. These are people who regularly go into their organizations, walk around, have the important conversations about getting better, building a respectful workplace, listening carefully, building trust and interdependence, and helping the people to be the best they can be. They create environments where it is safe to openly talk together, ask questions, share information, think out-loud and build a better future.

Leaders are people who have a vision of what is possible, are concerned and care enough to make a difference, have the courage and commitment to do the work, and truly engage with people to learn, grow and to achieve their results. These are people who regularly go into their organizations, walk around, have the important conversations about getting better, building a respectful workplace, listening carefully, building trust and interdependence, and helping the people to be the best they can be. They create environments where it is safe to openly talk together, ask questions, share information, think out-loud and build a better future. Lots of managers talk about the need for organizations to change and improve. But as I talk with people, go to conferences and read the safety literature, I hardly ever encounter anyone leading this way. So many managers do not know what it means to lead.

Lots of managers talk about the need for organizations to change and improve. But as I talk with people, go to conferences and read the safety literature, I hardly ever encounter anyone leading this way. So many managers do not know what it means to lead. Todd Conklin works with companies to help them recover and begin to heal after they have experienced a fatality in their workforce. He has come up with a different, creative way to look why the number of fatalities at work has remained at about 4,700 people a year for a number of years. Our programs of focusing on accident prevention have significantly reduced the total number of recordable injuries, but they have not had much impact on reducing the number of fatalities.

Todd Conklin works with companies to help them recover and begin to heal after they have experienced a fatality in their workforce. He has come up with a different, creative way to look why the number of fatalities at work has remained at about 4,700 people a year for a number of years. Our programs of focusing on accident prevention have significantly reduced the total number of recordable injuries, but they have not had much impact on reducing the number of fatalities. I just saw an announcement that the Liberty Mutual Research Institute for Safety was closing after 59 years, to reduce costs. The ISO 45001 Standard is in the final stages and is aimed at improving safety around the world. Yet some people are reacting that it will not make a difference because of management indifference or cost restraints.

I just saw an announcement that the Liberty Mutual Research Institute for Safety was closing after 59 years, to reduce costs. The ISO 45001 Standard is in the final stages and is aimed at improving safety around the world. Yet some people are reacting that it will not make a difference because of management indifference or cost restraints. Many of you who have been reading this newsletter know that our emphasis is on Partner Centered Leadership. We emphasize the importance of supervisors and managers getting into their workplaces each day and talking with the people. Talking with the people is a key to breaking through to safety excellence. Talking about the risks they face each day, how they are managing them, how their kids are doing, how the safety is doing, how the business is doing, asking them what they see as to ways to improve their own work, asking about problems they are dealing with, etc. Doing this with respect and really listening are vitally important.

Many of you who have been reading this newsletter know that our emphasis is on Partner Centered Leadership. We emphasize the importance of supervisors and managers getting into their workplaces each day and talking with the people. Talking with the people is a key to breaking through to safety excellence. Talking about the risks they face each day, how they are managing them, how their kids are doing, how the safety is doing, how the business is doing, asking them what they see as to ways to improve their own work, asking about problems they are dealing with, etc. Doing this with respect and really listening are vitally important.

As the snow begins to melt and the spring winds arrive, it is time for cleaning up the place. Mud season is upon us as the snow melts. All sorts of curious things emerge from the melting piles of snow; stuff that was covered up and lost. (Just imagine: Years ago the settlers kept their animals sheltered next to their houses or barns attached to their houses so that they could care for them when the winter cold set in. They really had to do the spring-cleaning!)

As the snow begins to melt and the spring winds arrive, it is time for cleaning up the place. Mud season is upon us as the snow melts. All sorts of curious things emerge from the melting piles of snow; stuff that was covered up and lost. (Just imagine: Years ago the settlers kept their animals sheltered next to their houses or barns attached to their houses so that they could care for them when the winter cold set in. They really had to do the spring-cleaning!)

We know that it can, and we prove it over and over again, as we work with leaders, their teams, and their businesses.

We know that it can, and we prove it over and over again, as we work with leaders, their teams, and their businesses. As this year comes to an end, we will be looking at our overall performance to see how we did and to plan for 2017. We will usually look at our injury statistics like the total recordable injury rate and try to determine how we performed. Often quite independently, others will look at other performance indicators to see how they came out. We act as if these are independent of each other, but in our organizations everything is connected so all aspects of performance influence each other. Everything happens through the people. All the parts are interconnected. Excellence in safety performance is strongly related to our total performance because it all works through the will of the people.

As this year comes to an end, we will be looking at our overall performance to see how we did and to plan for 2017. We will usually look at our injury statistics like the total recordable injury rate and try to determine how we performed. Often quite independently, others will look at other performance indicators to see how they came out. We act as if these are independent of each other, but in our organizations everything is connected so all aspects of performance influence each other. Everything happens through the people. All the parts are interconnected. Excellence in safety performance is strongly related to our total performance because it all works through the will of the people. Work-as-imagined and work-as-done are ideas developed by Erik Hollnagel in his book, Safety-I and Safety-II (2014. Ashgate Publishing Ltd., UK). Safety I is our traditional top-down management approach to safety management where rules and procedures are issued by those far from the actual work. This is like the approach discussed in the proceeding paragraph. I think that a lot of people are trying to do good safety work from the Safety I perspective, but the results are not improving fast enough.

Work-as-imagined and work-as-done are ideas developed by Erik Hollnagel in his book, Safety-I and Safety-II (2014. Ashgate Publishing Ltd., UK). Safety I is our traditional top-down management approach to safety management where rules and procedures are issued by those far from the actual work. This is like the approach discussed in the proceeding paragraph. I think that a lot of people are trying to do good safety work from the Safety I perspective, but the results are not improving fast enough.