A very effective leading indicator relating to occupational safety is to see and keep track of how people are working, and paying attention to details. These are called Safe Acts Audits. We look at a significant number of people doing their day-to-day jobs and keep track of what we see over time.

The way people choose to do a job is very strongly influenced by what is happening in the working environment, the culture—which strongly impacts their thinking. All that is rushing around in their minds (work, family, home, sports, politics) at the point of making a decision and acting on it is really important. Feeling pressured, rushed, bullied, undervalued, disrespected, not listened to, being pushed around by their supervisor, etc. are systems problems that create cloudy thinking resulting in someone getting hurt.

When these poor behaviors, done by individuals, persist over time it is clear that they are tolerated by management; I refer to them as systems problems. We can try to address these each time they arise, but if they keep coming up and the system does not change, they are systems problems.

When we observe people working safely (this is most of the people) we praise their safety efforts, and when we see someone working unsafely we need to pay attention and work together to correct the systems problems that are negatively impacting them. The openness we advocate where it is okay to talk about these things, to challenge decisions, to ask for help, to stop a job if they feel it is unsafe, is called Partner-Centered Safety.

If the ratio of the number of people we observe working safely (most of the people) compared to those working unsafely (very few people) drops, that is we see relatively more people working unsafely, we know that something has changed and must be addressed immediately.

We call this ratio the Safe Acts Index. When the Safe Acts Audits are done 2-3 times a week we can stay close to the current climate and react quickly to a drop in the Index by raising awareness, increasing the number of safety conversations, by helping everyone to become aware of a change and to use extra alertness looking out for and helping each other. In our experience, when the Index drops an injury occurs within the next 2-3 days unless the level of awareness and concern is promptly raised.

Safety excellence is achieved and sustained one day at a time, day after day.

Safety excellence is achieved and sustained one day at a time, day after day.

In Partner-Centered Safety we can do this together. Give us a call — let’s talk about how you and your team can reap the safety benefits of this unique-and-clearly-successful, focused way to eliminate injuries and incidents in your workplace.

Next month, we’ll discuss the leading indicators for occupational health and process safety management.

There is no doubt that work in the oil and gas industry is tough and dangerous, but that is no excuse for disregarding the health and safety of the workers. Almost all the deaths occurred when safety procedures were not followed. There is plenty of safety information available relating to tank cleaning. Have we not learned the lessons of improper confined space/vessel entry?

There is no doubt that work in the oil and gas industry is tough and dangerous, but that is no excuse for disregarding the health and safety of the workers. Almost all the deaths occurred when safety procedures were not followed. There is plenty of safety information available relating to tank cleaning. Have we not learned the lessons of improper confined space/vessel entry?

When I began to learn about chaos and complexity science, I saw that this was the way to handle the high level of change. As we shared more and more information, helped people to really understand the nature of the business and their important roles in its success, and as we built more trust and interdependence, people began to step forward to help us take on all the changes that poured into our organization. I did not have to do everything myself, which was a great relief.

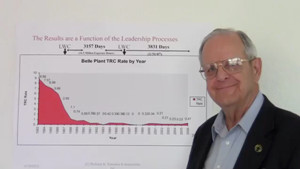

When I began to learn about chaos and complexity science, I saw that this was the way to handle the high level of change. As we shared more and more information, helped people to really understand the nature of the business and their important roles in its success, and as we built more trust and interdependence, people began to step forward to help us take on all the changes that poured into our organization. I did not have to do everything myself, which was a great relief. It was fascinating to see the contrast between the usual, linear, mechanical approach to safety and The Complexity Leadership Process (CLP) that I discussed at my display table. A large number of people talked with me at my display table about The Complexity Leadership Process which was new to all of them. Many could not believe how quickly and dramatically the safety performance improved using the CLP. At one level the CLP looks like a simple employee involvement program, yet it is much more and also different at a deeper level than the usual employee involvement processes. One fellow, who recently wrote a book about changing the safety culture to excellence just brushed the CLP aside as something he’d already seen. The approach to safety excellence he’s written about involves 43 linear steps that take 3-5 times as long as the CLP and require a very high level of persistence and determination over many years.

It was fascinating to see the contrast between the usual, linear, mechanical approach to safety and The Complexity Leadership Process (CLP) that I discussed at my display table. A large number of people talked with me at my display table about The Complexity Leadership Process which was new to all of them. Many could not believe how quickly and dramatically the safety performance improved using the CLP. At one level the CLP looks like a simple employee involvement program, yet it is much more and also different at a deeper level than the usual employee involvement processes. One fellow, who recently wrote a book about changing the safety culture to excellence just brushed the CLP aside as something he’d already seen. The approach to safety excellence he’s written about involves 43 linear steps that take 3-5 times as long as the CLP and require a very high level of persistence and determination over many years. I’ll be participating as a sponsor for the Conference Program Brochure. I’ll have an ad in the Brochure as well as a display table. My tag line is “When safety gets right, everything else gets right”. Since I am not an official speaker, I am going to use my display table as an opportunity to talk with people about the

I’ll be participating as a sponsor for the Conference Program Brochure. I’ll have an ad in the Brochure as well as a display table. My tag line is “When safety gets right, everything else gets right”. Since I am not an official speaker, I am going to use my display table as an opportunity to talk with people about the  This Blog is focused on my new book, The Process Enneagram©: Essays on Theory and Practice. I am the editor for this book that was just published by Emergent Publications. It can be purchased directly from their

This Blog is focused on my new book, The Process Enneagram©: Essays on Theory and Practice. I am the editor for this book that was just published by Emergent Publications. It can be purchased directly from their  Overlap: All three of these areas of safety are often lumped together as SHE, EHS or HSE. When we lump these all together we can miss things so I think it is useful to see these three overlapping, interacting areas of our safety and health work. There is some overlap between Occupational Safety and Occupational Health like the proper selection and use of respirators. There is some area of overlap between Occupational Health and Process Safety like preventing chronic exposures to toxic chemicals. There is some overlap between Process Safety and Occupational Safety like locating trailers and offices away from operating areas using large quantities of flammable and explosive materials.

Overlap: All three of these areas of safety are often lumped together as SHE, EHS or HSE. When we lump these all together we can miss things so I think it is useful to see these three overlapping, interacting areas of our safety and health work. There is some overlap between Occupational Safety and Occupational Health like the proper selection and use of respirators. There is some area of overlap between Occupational Health and Process Safety like preventing chronic exposures to toxic chemicals. There is some overlap between Process Safety and Occupational Safety like locating trailers and offices away from operating areas using large quantities of flammable and explosive materials.