Safety and Environmental Performance

When I was the Plant Manager of the DuPont Belle, West Virginia chemical plant, I developed a practice of walking around the Plant 4-5 hours a day, every day for almost 8 years, for the safety of the employees. The plant was a mile long and a third of a mile wide, with about 1,300 people working there.

I needed to engage with everyone to get to know them, their work, and to see what I could do to help them. I did not make decisions as I walked around, since that would weaken the line supervision. I would talk about our mission of being the best we could be with our responsibilities for safety, the environment, the people, the quality of our products and work, our customers, our customer service, our costs, and our community. I would share the news of the day, talking openly about things I knew about the plant, our businesses, and the community.

I would also ask if they had any news to share. I would ask for help in how I could improve my own job. There was a lot of give and take; some days were great and some were very hard. My mantra was, “I don’t have a right to make my living at a place where it was okay for you to get hurt. We also need to make a living so let’s figure this out together.”

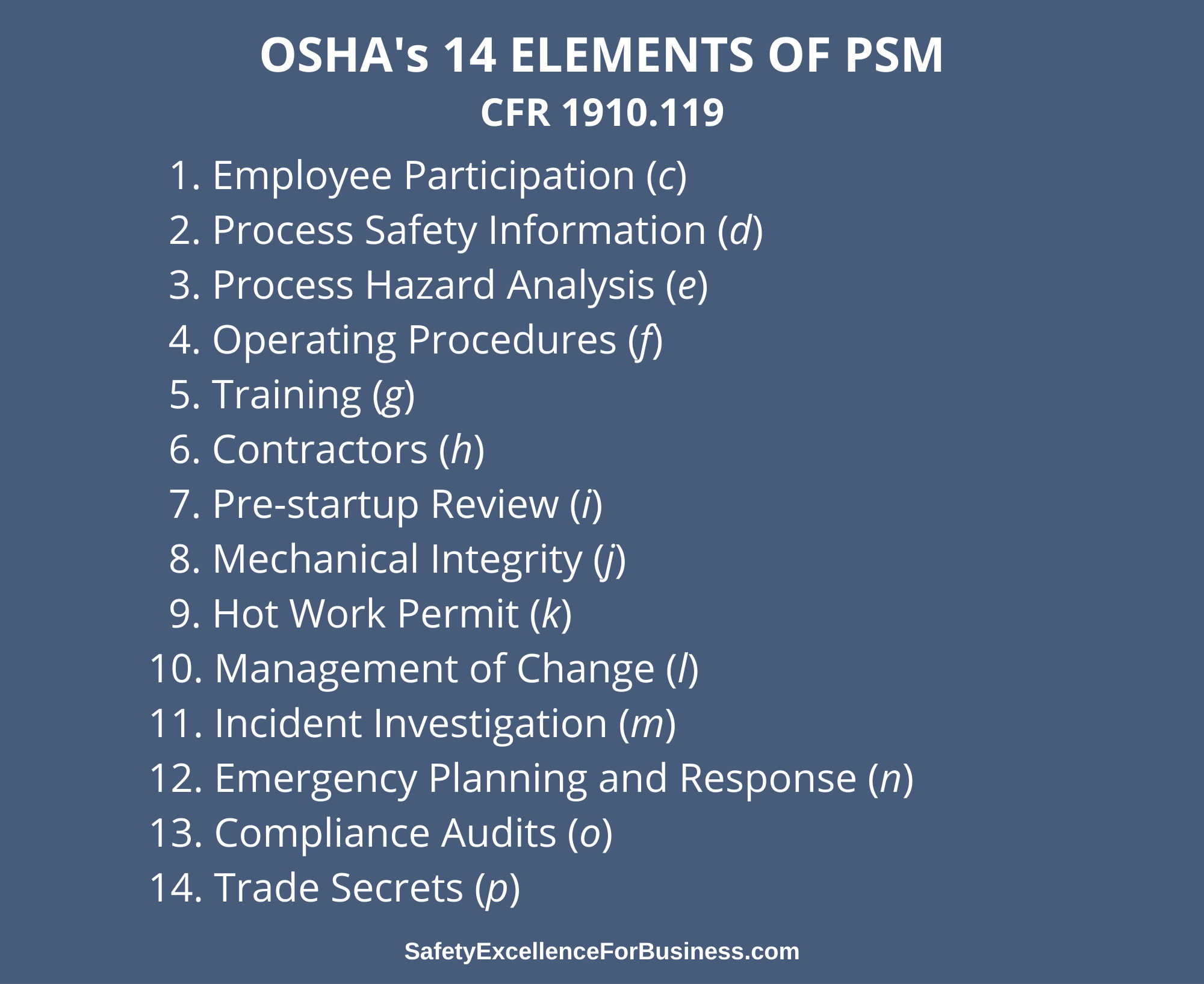

In our conversations, we talked a lot about occupational safety and occupational health. Many good ideas emerged. I would encourage the people to follow-up on their good ideas and support them. We would also talk about process safety management and the importance of keeping the chemicals in the pipes, improving yields, and reducing waste.

I encouraged them to go after leaks and to talk with the engineers about how they could run the processes better. I encouraged the engineers to teach the supervisors and operators about the theory and processes they were running. I encouraged them to learn as much as they could. I would ask about the safety and environmental maintenance work orders and if they were being taken care of promptly. When people asked me questions I couldn’t answer, I told them I did not know the answer, and promised to get back to them with the answer, which I always did.

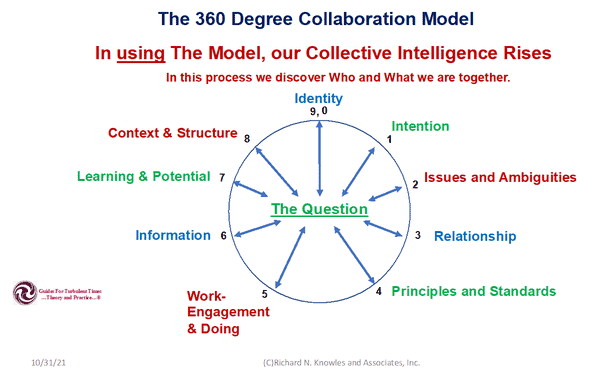

We had a Central Safety Committee of about 50 people, which met monthly. People from across the organization participated and led the various committees. We integrated all our discussions, so everyone was thinking about their roles in improving occupational safety, health, and process safety. The 4-person safety group, operators, mechanics, supervisors, and engineers were all involved.

While each of the three parts of safety have their own technology, they all overlap in the people doing the work. We saw all aspects of safety and environmental performance as an integrated whole where everyone could make contributions. As the safety and environmental improvements built, this way of working, sharing information, building respect and trust, and helping people to see the importance of their contributions and to find meaning, spread all across the plant.

Treating the People with Respect and Building Trust

In addition to improving our safety and business performance, we emphasized the importance of treating people with respect and telling the truth. I modeled this as I walked around and visited with the people. I apologized for the mistakes I made. I encouraged them to talk together this way as well. I also worked hard to eliminate any bullying or harassment behavior because it is bad for the people and blocks the open flow of information, greatly hindering any improvement efforts. As it became safer for people to speak up and share their ideas and thinking, our total performance significantly improved. Everything happened through the people giving their energy, creativity, and resourcefulness.

The Integrated Whole

Everyone does some of each of these three phases of safety in their jobs. While each of these has different technologies and requirements, they are all in play all the time. For example, an operator moving a container of chemicals needs to be wearing the correct PPE, lifting correctly and being sure that nothing gets spilled. Or a clerical person needs to be seated properly to take care of their back, handling office equipment like scissors carefully, and putting their trash into the proper containers. Or a truck driver needs to use three-point contact when entering and exiting his truck to prevent a fall, have proper cushioning in the truck to support their back and adhere to speeds that are appropriate for the highway conditions.

All dimensions of safety are taking place all the time, as each person does their work. Each person needs to integrate these as appropriate for their particular assignments and tasks. When these are an integrated whole, their jobs are much easier as they think about them together.

Having them as an integrated whole also goes a long way to preventing disasters like the Deep-Water Horizon where the people on the drilling platform received a safety prize for great occupational safety, and then the platform blew up a day or so later because the process safety was falling apart.

The work of the Belle Plant people clearly shows that if we approach safety as an integrated whole, the total performance of the people improves.

Summary

Trust was built, people opened up, shared their ideas, learned, made decisions about improving their work, and brought occupational safety, health, and process safety management together into an integrate whole. The mood of the entire organization became very positive as things came together. In just four years the people had cut our injury rate by 97% to a Total Recordable Injury Rate of 0.3, reduced our emissions to the air, water, and land by 95%, improved productivity by 45% and increased earnings 300%.

This integrated way of working can happen for your business too. Give me a call at 716-622-6467 for more details. Let’s get started! Please check out our website: Safety Excellence for Business.

The goal is to get through all this safely, keep your people and business thriving and active, building stronger relationships for partnering and working together. This is a tough challenge, but who knows your workplace and the people better than you. You can work things out together.

The goal is to get through all this safely, keep your people and business thriving and active, building stronger relationships for partnering and working together. This is a tough challenge, but who knows your workplace and the people better than you. You can work things out together.