Lots of organizations proclaim that “Safety is Number 1” or something like this. In my early years, I thought this way as well. In reality, we have to have both in order for the business to make money. I have talked about this before in other newsletters and in my talks at the ASSE Annual PDC Conferences.

Sometimes we need to work on and talk more about the safety hazards, needs and requirements. Other times we need to work on and talk about the production needs. Both Safety and production are always in the conversations; sometimes more of safety and other times more of production. This is a both/and situation.

We were always in this conversation when I was the plant manager and you can see from the results mentioned in the proceeding section, we were able to do very well in managing this dynamical balance. It is dynamical because, not only are the situations dynamic in themselves, but also there are many situations going on at the same time around them so everything is always moving. We have to be very alert, talk together, help each other work at our highest skill levels.

I love talking with people and getting to know them. Sometimes it is really interesting and sometimes it gets quite funny. The other night I was at the local piano bar, sitting between two older gentlemen. One was an 86-year-old retired colonel who was pretending to play his imaginary drums along with the piano player and the other guy introduced himself to me 5 times in the first 10 minutes. Sometimes you just don’t know until you start talking.

I love talking with people and getting to know them. Sometimes it is really interesting and sometimes it gets quite funny. The other night I was at the local piano bar, sitting between two older gentlemen. One was an 86-year-old retired colonel who was pretending to play his imaginary drums along with the piano player and the other guy introduced himself to me 5 times in the first 10 minutes. Sometimes you just don’t know until you start talking. Hardly any of us can do our best work all by ourselves.

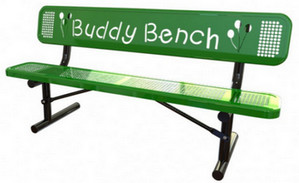

Hardly any of us can do our best work all by ourselves. There was a video on Facebook a few weeks ago about Buddy Benches being placed in schoolyards. The video explained the importance of the communication and training that is essential to their use and effectiveness.

There was a video on Facebook a few weeks ago about Buddy Benches being placed in schoolyards. The video explained the importance of the communication and training that is essential to their use and effectiveness. On December 16-18, 2015, I was able to attend the Cruise Line International Association Safety Conference in Miami. The focus was on improving the safety culture and Bridge Resource Management. This is a very interesting business for me to learn about. I was there to give some perspective from the chemical industry.

On December 16-18, 2015, I was able to attend the Cruise Line International Association Safety Conference in Miami. The focus was on improving the safety culture and Bridge Resource Management. This is a very interesting business for me to learn about. I was there to give some perspective from the chemical industry. There is a big need to be sure the managers of chemical plants are qualified so that their employees and neighboring communities do not suffer the consequences of chemical releases and spills. Many manufacturing businesses that do hazardous work, aside from chemical manufacturing, should heed this thinking too.

There is a big need to be sure the managers of chemical plants are qualified so that their employees and neighboring communities do not suffer the consequences of chemical releases and spills. Many manufacturing businesses that do hazardous work, aside from chemical manufacturing, should heed this thinking too. I’m reminded about the organization that thought their safety performance was always good, because they were primarily an office environment. They scoffed over how bad could a paper cut be? Or, what’s the worst that could happen if someone fell off their chair? Little did they expect that one of their office workers, when on a healthy outdoor walk during her scheduled break time, tripped over some roped off tape that had been blown by the wind. She actually walked into it – not paying attention to her surroundings – got caught up in it as it wrapped about her feet. She fell, twisted her knee, required surgical repair, etc., etc. Try to explain that office worker lost-time injury! (The good: healthy walk; The bad: not paying attention; The ugly: lost time injury).

I’m reminded about the organization that thought their safety performance was always good, because they were primarily an office environment. They scoffed over how bad could a paper cut be? Or, what’s the worst that could happen if someone fell off their chair? Little did they expect that one of their office workers, when on a healthy outdoor walk during her scheduled break time, tripped over some roped off tape that had been blown by the wind. She actually walked into it – not paying attention to her surroundings – got caught up in it as it wrapped about her feet. She fell, twisted her knee, required surgical repair, etc., etc. Try to explain that office worker lost-time injury! (The good: healthy walk; The bad: not paying attention; The ugly: lost time injury). We see organizations as complex adapting networks of people who are the vital keys to its success. When the people in the various parts of the network are sharing information and helping each other, all aspects of EHS Performance rapidly improves, resistance to change disappears and the energy bubbles up spilling over into all other parts of the work lifting the organization to new, higher levels of performance.

We see organizations as complex adapting networks of people who are the vital keys to its success. When the people in the various parts of the network are sharing information and helping each other, all aspects of EHS Performance rapidly improves, resistance to change disappears and the energy bubbles up spilling over into all other parts of the work lifting the organization to new, higher levels of performance. In many places, the hunting season is underway or just beginning. This is always a time of change and hazard. Some years when I was a plant manager, we would have one or two serious hunting-related, off-job injuries – like falling from a tree stand or tripping over something and breaking a leg. There is a lot of change as people go into the woods and fields looking for game. Many have not done this for a while. Others may not be fully prepared for a sharp change in the weather where a heavy rain could come in or the temperatures drop below freezing and hypothermia becomes a worry. It is often dark and visibility is poor. I have read of hunters getting killed with their own weapon when they have tripped and accidentally shot themselves. Don’t load your gun until you are ready to use it.

In many places, the hunting season is underway or just beginning. This is always a time of change and hazard. Some years when I was a plant manager, we would have one or two serious hunting-related, off-job injuries – like falling from a tree stand or tripping over something and breaking a leg. There is a lot of change as people go into the woods and fields looking for game. Many have not done this for a while. Others may not be fully prepared for a sharp change in the weather where a heavy rain could come in or the temperatures drop below freezing and hypothermia becomes a worry. It is often dark and visibility is poor. I have read of hunters getting killed with their own weapon when they have tripped and accidentally shot themselves. Don’t load your gun until you are ready to use it. I have been talking about checklists in my previous newsletters and they can be useful as people go out hunting.

I have been talking about checklists in my previous newsletters and they can be useful as people go out hunting. I recently read of a fatal accident where a man was killed while working on a lathe. It was properly shielded and okay for the normal conditions, but the unexpected happened. The part he was working on exploded apart under the high rotating speed when he engaged the cutter. The parts from the exploding piece went right through the shield and gave him terrible, fatal wounds.

I recently read of a fatal accident where a man was killed while working on a lathe. It was properly shielded and okay for the normal conditions, but the unexpected happened. The part he was working on exploded apart under the high rotating speed when he engaged the cutter. The parts from the exploding piece went right through the shield and gave him terrible, fatal wounds. Another thing that can happen around hunting season and the holidays is the need to hire temporary people to backfill for those who are out. These people need extra care and attention, but things are often so busy that it is hard to give it to them. These people just don’t know the hazards.

Another thing that can happen around hunting season and the holidays is the need to hire temporary people to backfill for those who are out. These people need extra care and attention, but things are often so busy that it is hard to give it to them. These people just don’t know the hazards. In many of my newsletters, I have talked about the importance of sharing information abundantly, building relationships of trust and interdependence, and helping people to see the importance of their own work in building the success of the whole organization.

In many of my newsletters, I have talked about the importance of sharing information abundantly, building relationships of trust and interdependence, and helping people to see the importance of their own work in building the success of the whole organization. At our exhibit booth, Claire and I shared our Partner-Centered Leadership approach. We handed out brochures and other literature that can help organization’s achieve safety excellence and move towards their OSHA Star designation. We were there to share important information, including the need to be able to lift up and address one’s safety elephants that are preventing organizations from being the best they can be.

At our exhibit booth, Claire and I shared our Partner-Centered Leadership approach. We handed out brochures and other literature that can help organization’s achieve safety excellence and move towards their OSHA Star designation. We were there to share important information, including the need to be able to lift up and address one’s safety elephants that are preventing organizations from being the best they can be. The keys for addressing both of these concerns in building sustainability into their programs and in achieving the OSHA Star status is for the people at all levels and parts of the organization to talk together to get clear and aligned on just what they really want to do. How sincere and authentic is the desire to have safety excellence for the long-term? (This means Communication with a Capital C—requiring Co-creation, Clarity and Coherence.) In addition, together they must take the time to co-create a set of ground rules about how they agree to work together in order to achieve their safety goals and then hold each other accountable to live up to them. (That’s Partnership and Commitment!) The process to achieve this is available to you and your organizations now.

The keys for addressing both of these concerns in building sustainability into their programs and in achieving the OSHA Star status is for the people at all levels and parts of the organization to talk together to get clear and aligned on just what they really want to do. How sincere and authentic is the desire to have safety excellence for the long-term? (This means Communication with a Capital C—requiring Co-creation, Clarity and Coherence.) In addition, together they must take the time to co-create a set of ground rules about how they agree to work together in order to achieve their safety goals and then hold each other accountable to live up to them. (That’s Partnership and Commitment!) The process to achieve this is available to you and your organizations now. This is all about having everyone go home in one piece and having a profitable business. Excellence in both the safety performance and business results are attainable.

This is all about having everyone go home in one piece and having a profitable business. Excellence in both the safety performance and business results are attainable. Talking together is one of the most important things we can do to help to improve the safety in our workplaces. Letting people know that you care about them and respect them. But too many times I have seen supervisors and managers talking down to their employees ordering them to do this or that.

Talking together is one of the most important things we can do to help to improve the safety in our workplaces. Letting people know that you care about them and respect them. But too many times I have seen supervisors and managers talking down to their employees ordering them to do this or that.