When leadership can help employees overcome feelings of impatience, frustration and anger, the energy and creativity of the people emerges, enabling much quicker, better decisions and more effective work to take place.

Impatience

In a long road trip over this Labor Day Weekend, we got stuck in an hour-long traffic jam on a very busy Interstate Highway. The GPS message was “Your route is closed.” We were sitting on the 3-lane highway with big trucks all around us and there was no way out.

My impatience level went way up as we just sat without knowing anything about the stoppage or a possible alternative way out. Other car drivers were also getting impatient and beginning to make poor decisions. For example, several impatient drivers wiggled thru tight spaces, actually turning their respective vehicles around – then began their journey against the normal traffic flow, maneuvering along the shoulder to get to the last exit we had passed so they could get off the Interstate and go around the holdup on secondary roads.

We just waited with the trucks to see what was going to happen. After about an hour the traffic began to move and open up. We never saw the source of the holdup, but we had a sigh of relief to be able to move forward again.

Ruminations

I began to think about the times in my own career when things got bogged down or we had had an incident that stopped everything. I struggled with these same feelings of impatience. Everyone was impatient and frustrated. Some people wanted to just push through before we had given things enough consideration to understand what was wrong and see a way out of the problem. Others spent time in their offices, away from the situation, trying to dictate solutions; it is easy to come up with possible solutions when you do not know what is really going on. This really became frustrating when the corporate people tried to tell us how to solve our problem. Others wanted to cut through the safety procedures since they felt the procedures were getting in our way.

We were all impatient, anxious, angry, struggling with a strong sense of urgency and frustration. This is a dangerous situation where it is very easy to make dreadful mistakes. The people working close to the problem feel acute pressure to solve the problem and get going. They are extremely aware that their managers want to get going. Their managers are also under a lot of pressure from their managers or from sales or from customers to get going.

The people working close to the problem are aware of all these pressures, but also know that they have to do things right so no one gets hurt, so the process will really run correctly when things are restored, and so there will not be a new safety or environmental incident on startup.

Leadership’s Role

In these situations of high frustration and impatience, the people close to the work need to be helped and supported by their management and leaders.

As a Plant Manager, my role was to create a safe space for those working close to the problem to think things through, organize themselves, plan the restoration processes, and make the other decisions needed to get back up and running safely. The operators, mechanics, engineers, and safety people know what needs to be done, so as the Plant Manager, my role was to create a safe space where they could do their work. I also reminded them to work with high safety, environmental and customer standards, helping each other to do their best in the situation.

As we shared information on the progress to solve the problem and the things around it, we also helped to maintain respect and caring among everyone and gave credit to them as progress was made. These made a big, positive difference.

When we can minimize the feelings of impatience, frustration and anger, the energy and creativity of the people emerges, enabling much quicker, better decisions and more effective work to take place. This is Partner-Centered Leadership in action!

Call me at 716-622-6467 and I’ll be pleased to talk to you about Partner-Centered Leadership. It is the way forward.

Learning to work more effectively, through our safety work, spread to the whole organization. Each of you reading this newsletter can make a big difference as you engage with the people in your organizations, sharing information, building respect and trust. The impact of your work will spread.

Learning to work more effectively, through our safety work, spread to the whole organization. Each of you reading this newsletter can make a big difference as you engage with the people in your organizations, sharing information, building respect and trust. The impact of your work will spread. The COVID-19 pandemic, the return to school questions, the protests and riots in so many of our cities, the bitter political campaign, the demand for using the “correct” words, are driving people crazy. The COVID-19, the questions, the anxieties and concerns, spill into our workplaces causing a lot of uncertainty and stress. We see this happening every day. Our businesses, our schools and hospitals, our governments, and not-for-profits, at all levels, are struggling. Changes and pressures are coming faster and faster.

The COVID-19 pandemic, the return to school questions, the protests and riots in so many of our cities, the bitter political campaign, the demand for using the “correct” words, are driving people crazy. The COVID-19, the questions, the anxieties and concerns, spill into our workplaces causing a lot of uncertainty and stress. We see this happening every day. Our businesses, our schools and hospitals, our governments, and not-for-profits, at all levels, are struggling. Changes and pressures are coming faster and faster. In thinking about your own place where you work, what do you suppose it would be like if you did some of these things? Do you think that you could begin talking with others about the COVID-19 challenges and building a more respectful environment? What do you think it would be like if you could openly talk together about the important issues like workable, social distancing and improving the safety of your job?

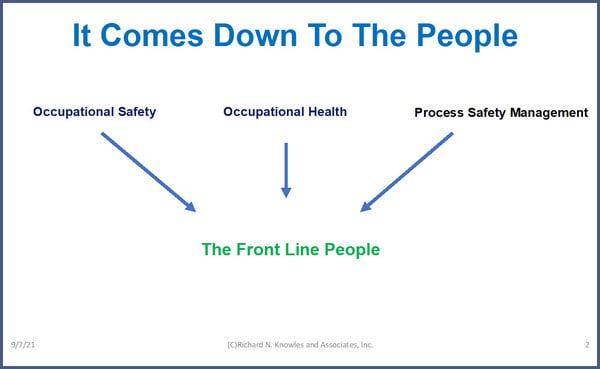

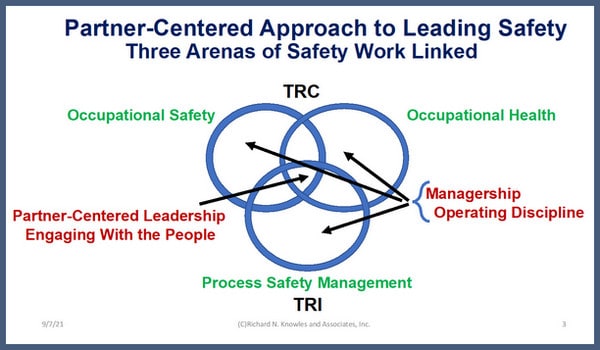

In thinking about your own place where you work, what do you suppose it would be like if you did some of these things? Do you think that you could begin talking with others about the COVID-19 challenges and building a more respectful environment? What do you think it would be like if you could openly talk together about the important issues like workable, social distancing and improving the safety of your job? When I was transferred to the DuPont Belle, West Virginia plant in 1987, the Total Recordable Injury Case Rate (TRC) was about 5.8 and emissions to air, water and ground, as reported in the EPA Toxic Release Inventory (TRI) annual report, was over 6,000,000 pounds/year. Within three years, both of these had dropped by about 95% to a TRC of about 0.3 and a TRI of about 275,000 pounds/year. Emissions to the environment is one way to measure how well the process safety is working; the better the process safety work, the lower the emissions to the environment.

When I was transferred to the DuPont Belle, West Virginia plant in 1987, the Total Recordable Injury Case Rate (TRC) was about 5.8 and emissions to air, water and ground, as reported in the EPA Toxic Release Inventory (TRI) annual report, was over 6,000,000 pounds/year. Within three years, both of these had dropped by about 95% to a TRC of about 0.3 and a TRI of about 275,000 pounds/year. Emissions to the environment is one way to measure how well the process safety is working; the better the process safety work, the lower the emissions to the environment. The process safety management collapsed in January of 2010 with major, accidental releases to the air and river and they had a man get killed with a phosgene release. When the US Chemical Safety Board investigated in late 2010, they reported that while the occupational safety and health performance was the best in the DuPont Company, the process safety management had fallen apart and the plant was not even using the DuPont standard procedures. This was a sad commentary about how far things had fallen.

The process safety management collapsed in January of 2010 with major, accidental releases to the air and river and they had a man get killed with a phosgene release. When the US Chemical Safety Board investigated in late 2010, they reported that while the occupational safety and health performance was the best in the DuPont Company, the process safety management had fallen apart and the plant was not even using the DuPont standard procedures. This was a sad commentary about how far things had fallen. Artificial intelligence and robots, block chains and bitcoins, the opioid epidemic, political strife, and workplace violence, international worries and potential conflicts are some of the challenges facing all of us. There is a critical need for people, in all walks of life, to come together to openly and honestly talk about our challenges, share our thinking and learn together. We do not have to be blindly swept along. We can make decisions and do the things that we need to do to help to make the world a better place.

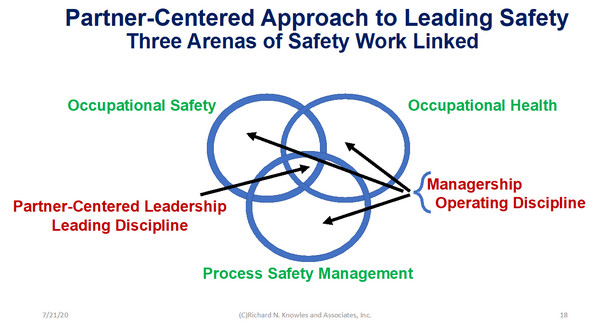

Artificial intelligence and robots, block chains and bitcoins, the opioid epidemic, political strife, and workplace violence, international worries and potential conflicts are some of the challenges facing all of us. There is a critical need for people, in all walks of life, to come together to openly and honestly talk about our challenges, share our thinking and learn together. We do not have to be blindly swept along. We can make decisions and do the things that we need to do to help to make the world a better place. When I talk about safety. my thinking goes well beyond the traditional safety numbers, training and procedures. It includes ideas about respect and how everyone has agreed to work together. It includes ideas about personal responsibility, integrity and dedication to helping everyone improve. It includes openness, honesty and sharing information abundantly. It includes ideas about the deeper, often hidden patterns of behavior which have a profound impact on the work environment and drive much of the behavior. It includes the fact that the managers and leaders have the largest impact on their organization’s performance. It includes the understanding that managers focus on reliability, stability, predictability and control as they try to maintain the status quo and that leaders focus on the people, change and the future sharing information abundantly, treating people with respect and helping people find meaning in their work. Both good leaders and managers are needed.

When I talk about safety. my thinking goes well beyond the traditional safety numbers, training and procedures. It includes ideas about respect and how everyone has agreed to work together. It includes ideas about personal responsibility, integrity and dedication to helping everyone improve. It includes openness, honesty and sharing information abundantly. It includes ideas about the deeper, often hidden patterns of behavior which have a profound impact on the work environment and drive much of the behavior. It includes the fact that the managers and leaders have the largest impact on their organization’s performance. It includes the understanding that managers focus on reliability, stability, predictability and control as they try to maintain the status quo and that leaders focus on the people, change and the future sharing information abundantly, treating people with respect and helping people find meaning in their work. Both good leaders and managers are needed. We know that it can, and we prove it over and over again, as we work with leaders, their teams, and their businesses.

We know that it can, and we prove it over and over again, as we work with leaders, their teams, and their businesses. Partner-Centered Safety is a robust, proven way to bring people together to achieve sustainable levels of safety excellence being based on deeply held beliefs and values.

Partner-Centered Safety is a robust, proven way to bring people together to achieve sustainable levels of safety excellence being based on deeply held beliefs and values.