I found several papers from “America’s Safest Companies Conference” last year quite interesting.

One by Terry L. Mathis discussed his new book (co-Authored by Shawn M. Galloway) called “Steps to Safety Culture Excellence.” This book describes, very nicely, 43 steps that can lead to safety excellence using the more traditional approach coming out of the Newtonian/Cartesian paradigm where we see cause/effect relationships, linear processes and big results needing big efforts. A lot of their ideas are quite good.

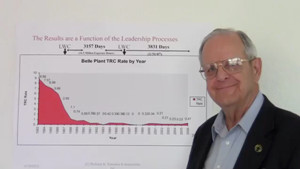

Another paper from an award-winning company showed their outstanding progress in lowering their total recordable injury rate from around 10 to 0.5 through a steady progress of improvements over 10 years. Their work was out of the Newtonian/Cartesian perspective, quite similar to what Mathis and Galloway teach.

Another paper from an award-winning company showed their outstanding progress in lowering their total recordable injury rate from around 10 to 0.5 through a steady progress of improvements over 10 years. Their work was out of the Newtonian/Cartesian perspective, quite similar to what Mathis and Galloway teach.

The new book by Sydney Dekker, “Drifting into Failure,” discusses the importance of seeing the world from the complex systems perspective. This is the perspective from which I have worked for so many years. In using this approach when I was the Plant Manager at the DuPont Belle, West Virginia Plant, we cut the total recordable injury rate from about 5.8 to below 0.3 in just three years and sustained this for 17 years. When I was leading the transformational work in New Zealand Steel, in the work described by Stephen Zafron and David Logan in their book “The Three Laws of Performance,” we worked from the complexity perspective. The total recordable injury rate at New Zealand Steel dropped by about 50% in just a year and a half.

The lesson here is quite clear. If you want to try to reach safety excellence using the Newtonian/Cartesian approach and taking 10 years to do it, then that is your choice. Doing this over 10 years requires a lot of hard, dedicated work to sustain the effort.

On the other hand, if you want to achieve excellence in safety in just two-three years, then you need to work from the complexity perspective. Not only is the process quicker, you have many fewer injuries along the way. It takes courage, persistence and commitment to make this happen.

It is clear that the approach from the complexity perspective is superior, achieving excellence more quickly with fewer injuries along the way. Leading the journey to safety excellence from the complexity perspective is what we call Self-Organizing Leadership and we use the Complexity Leadership Process to do this.

Several web sites have useful information relating to this way of leading and working:

Safety Excellence for Business

Center for Self-Organizing Leadership

Let’s not lose sight of our objective: We want everyone to leave the workplace at the end of their workday or shift without getting hurt—no injuries! Safety is an everyday, every minute dynamic, starting now!

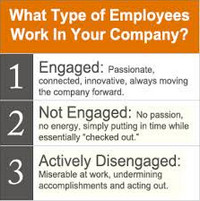

But, the machine view of organizations is the dominant paradigm right now. We direct the people to work in tight procedures. We manipulate them to do things right. We punish them when there is an injury or incidents. We look for root-cause. We think that if we can take things apart and understand the parts that we can understand the whole. Almost all the effort is engaged in doing things TO the people as if they were just interchangeable parts of a machine. Most people push back against authority in this paradigm. This is a win/lose environment.

But, the machine view of organizations is the dominant paradigm right now. We direct the people to work in tight procedures. We manipulate them to do things right. We punish them when there is an injury or incidents. We look for root-cause. We think that if we can take things apart and understand the parts that we can understand the whole. Almost all the effort is engaged in doing things TO the people as if they were just interchangeable parts of a machine. Most people push back against authority in this paradigm. This is a win/lose environment. People are often reluctant to speak up in these negative environments. Ideas for improvement never surface. New employees are negatively influenced and led astray. Supervisors have a very rough time getting the people to do their work properly. Grievance rates are high and much time is wasted needlessly because these are not addressed at an early stage.

People are often reluctant to speak up in these negative environments. Ideas for improvement never surface. New employees are negatively influenced and led astray. Supervisors have a very rough time getting the people to do their work properly. Grievance rates are high and much time is wasted needlessly because these are not addressed at an early stage. Partner-Centered Safety is a robust, proven way to bring people together to achieve sustainable levels of safety excellence being based on deeply held beliefs and values.

Partner-Centered Safety is a robust, proven way to bring people together to achieve sustainable levels of safety excellence being based on deeply held beliefs and values. Most of us working in safety have been brought up to see organizations as if they are machine-like. This thinking goes all the way back to Descartes (1596-1650) and Newton (1642-1727). We use reductionist approaches to try to understand them. We seek cause/effect relationships. We use linear processes for training and the like, prescribing answers and doing things TO the people. We work on this part or that part trying to fix the whole thing.

Most of us working in safety have been brought up to see organizations as if they are machine-like. This thinking goes all the way back to Descartes (1596-1650) and Newton (1642-1727). We use reductionist approaches to try to understand them. We seek cause/effect relationships. We use linear processes for training and the like, prescribing answers and doing things TO the people. We work on this part or that part trying to fix the whole thing.

Lots of critical knowledge, experience and skills will be lost. Younger people, who have grown up in an electronic world of texting and games, will replace these people. Many are out of shape and bordering on being over weight; some are developing diabetes. This will pose significant challenges to employers and the need to work safely and well.

Lots of critical knowledge, experience and skills will be lost. Younger people, who have grown up in an electronic world of texting and games, will replace these people. Many are out of shape and bordering on being over weight; some are developing diabetes. This will pose significant challenges to employers and the need to work safely and well.