Every now and then a major disaster occurs in high-consequence industries like chemical manufacturing, petroleum production, refining, and aviation.

These disasters tend to be low-frequency events, which often look like some big surprise just happened. A lot of people get killed and severe damage to their facilities, their customers and the environments results. Often things looked like they were going fine just before the disaster strikes.

For example, the workers on the Deepwater Horizon drilling platform received good recognition for outstanding occupational safety performance (the slips, trips and falls sorts of incidents) just a day or two before the explosion on April 20, 2010, that killed 11 people and injured 17 others. The pressures from top management to get into production led to failures of their process safety management (PSM) systems and processes. Communications were limited because management did not want to hear of more problems; they were driving the production schedule. The fine occupational safety performance masked the PSM deficiencies which are more subtle and invisible to upper managers, unless they are keenly aware of the needs for excellent PSM.

For example, the workers on the Deepwater Horizon drilling platform received good recognition for outstanding occupational safety performance (the slips, trips and falls sorts of incidents) just a day or two before the explosion on April 20, 2010, that killed 11 people and injured 17 others. The pressures from top management to get into production led to failures of their process safety management (PSM) systems and processes. Communications were limited because management did not want to hear of more problems; they were driving the production schedule. The fine occupational safety performance masked the PSM deficiencies which are more subtle and invisible to upper managers, unless they are keenly aware of the needs for excellent PSM.

Part of being keenly aware is getting out of their offices and into the field looking, listening, talking with the people, and learning what is really going on. The gap between PSM-as-imagined and PSM-as-done was huge. When the pressures for production begin to overwhelm the safety systems, red flags need to be raised. The culture needs to be one where people can bring up problems and challenge the pressures without sacrificing their careers.

Another example occurred at the DuPont Belle, West Virgina plant (now Chemours) where I was the plant manager. I used the Partner-Centered Leadership (PCL) approach when I was there. I spent 5 hours a day in the plant looking, listening, talking with the people, and helping to build higher standards and performance. Along with all our other improvements, our occupational safety and ergonomics injury rates (Total Recordable Case Rate (TRC) dropped by over 97% to about 0.3 and emissions to air, water and land (a measure of our PSM performance) dropped by over 95%.

When I was transferred, the people close to the actual work continued to self-manage themselves with all we had learned about PCL, and their TRC stayed around 0.3 for 12 more years. However, the new managers that came after me used the traditional top-down approach and pulled lots of the PSM decision-making up to themselves. The TRC rates were so good that they left the people close to the work using PCL alone. The managers started to cut corners by limiting funds, cutting back on engineering support, letting inspection timelines slip, and the like. While the TRC looked great, the PSM was slowly rotting away and things fell apart.

They eventually had a series of disasters and an operator was killed. The managers hardly got out of their offices, lost contact with the people, let the standards slip and trust fell apart with the result that the gap between work-as-imagined and work-as-done became very wide. This sounds like the Deepwater Horizon pattern.

Safety in High-Consequence Industries

Now we have another example with the mess at Boeing and the 737 Max crashes. Top management was feeling the pressures for market share from Airbus and putting terrific pressures on cost reduction and faster production.

Now we have another example with the mess at Boeing and the 737 Max crashes. Top management was feeling the pressures for market share from Airbus and putting terrific pressures on cost reduction and faster production.

According to an April New York Times story, the people were forced to take short cuts, and about a dozen whistle-blower claims and safety complaints on things like defective manufacturing, quality problems, and debris left on planes were ignored. Training of pilots was shorted from 4 to 2 sessions in flight simulators. These problems went from the top of the organization all the way down. Now after two crashes 346 people are dead. There is a lot left in this story as it unfolds. Again, this pattern is like the first two stories.

In these high consequence industries, the top management needs to have a discipline of raising red flags when they are feeling the pressures to hurry up, cut costs and produce more. These pressures shutdown and destroy the communications, quality, and safety standards. This takes discipline and courage but that is the nature of the business. Leading businesses where there are high-consequence, low frequency events requires focus, skill and leading using the PLC approach.

When the system fails, it is not the top managers who get killed!

This is quite attainable with authentic, courageous leaders who take a stand that this is the sort of place they want to lead. The knowledge and technology are available and broadly known by lots of people so I want to share my own experiences.

This is quite attainable with authentic, courageous leaders who take a stand that this is the sort of place they want to lead. The knowledge and technology are available and broadly known by lots of people so I want to share my own experiences. This all began with my determination to work on improving respect, civility and safety. As I built credibility and trust with everyone, people began to make improvements in many other areas. Everything got better.

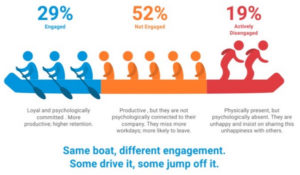

This all began with my determination to work on improving respect, civility and safety. As I built credibility and trust with everyone, people began to make improvements in many other areas. Everything got better. In 2017, Gallup, Inc. published their “State of the Global Workplace,” looking at the levels of productivity around the world. They were concerned about the decline in productivity and wanted to develop a better picture of the situation. High productivity is a key to having a good quality of life, and this relates to how involved people are in their work. They found that worldwide, only about 15% of the people are highly involved. This varies from country to country with the highest levels of involvement in the USA and Canada at 31%. Those businesses in the top quartile of employee involvement in their global study are 21% more profitable and 17% more productive. They also have 70% fewer safety incidents, 40% fewer quality incidents, 41% lower absenteeism, and 59% lower turnover. The positive impact of employees being highly involved is huge.

In 2017, Gallup, Inc. published their “State of the Global Workplace,” looking at the levels of productivity around the world. They were concerned about the decline in productivity and wanted to develop a better picture of the situation. High productivity is a key to having a good quality of life, and this relates to how involved people are in their work. They found that worldwide, only about 15% of the people are highly involved. This varies from country to country with the highest levels of involvement in the USA and Canada at 31%. Those businesses in the top quartile of employee involvement in their global study are 21% more profitable and 17% more productive. They also have 70% fewer safety incidents, 40% fewer quality incidents, 41% lower absenteeism, and 59% lower turnover. The positive impact of employees being highly involved is huge. Most people in management positions focus on systems and processes like running a payroll or production line. They want reliability, predictability, control, and stability, which are important for much of the business. But when they apply this approach to people, things go downhill. This approach results in 71% of the people globally being unengaged and 19% being actively disengaged. Morale, safety and engagement are a mess. Managers engage in managership, and this will not solve the problem of building higher levels of engagement.

Most people in management positions focus on systems and processes like running a payroll or production line. They want reliability, predictability, control, and stability, which are important for much of the business. But when they apply this approach to people, things go downhill. This approach results in 71% of the people globally being unengaged and 19% being actively disengaged. Morale, safety and engagement are a mess. Managers engage in managership, and this will not solve the problem of building higher levels of engagement.

The way in which we think about and work with all the people is a key shift that is needed.Leading thinkers like Eric Hollnagel, Tom McDaniel, Beth Lay, Carl Stent, and Ron Gantt are searching for better, more effective ways of engaging with everyone to build on the good things people are doing.

The way in which we think about and work with all the people is a key shift that is needed.Leading thinkers like Eric Hollnagel, Tom McDaniel, Beth Lay, Carl Stent, and Ron Gantt are searching for better, more effective ways of engaging with everyone to build on the good things people are doing.