The March 24, 2025 ASIS Newsletter by Scott Briscoe reports Characteristics of Fatal Workplace Violence Incidents.

You can click here to view this report on workplace violence incidents.

Most people will not experience a tragedy or workplace violence like this, but when this happens, everything changes immediately. Are you prepared to even think about this? Do you ever run a co-worker’s suicide scenario through your mind and wonder how you would handle it? The larger your work force is, the more likely you will have a suicide incident. Many people have firearms. What is the policy about firearms in your organization?

I have had several acquaintances at work (I was a chemist in a laboratory) who used lab chemicals like sodium cyanide to kill themselves at work. They were struggling with a lot of pressure at work and felt they were not being treated fairly. Their dreams were not being fulfilled and no one cared about them.

Do you have people in your organization struggling like this? Have you looked around to see if people are cared about and treated fairly? I had not looked around and was unaware of their struggles. Maybe I could have made a difference.

Have you ever thought about having someone come into your workplace and kill someone? These things do not happen very often, but now and then someone gets killed and we do not know where that will happen.

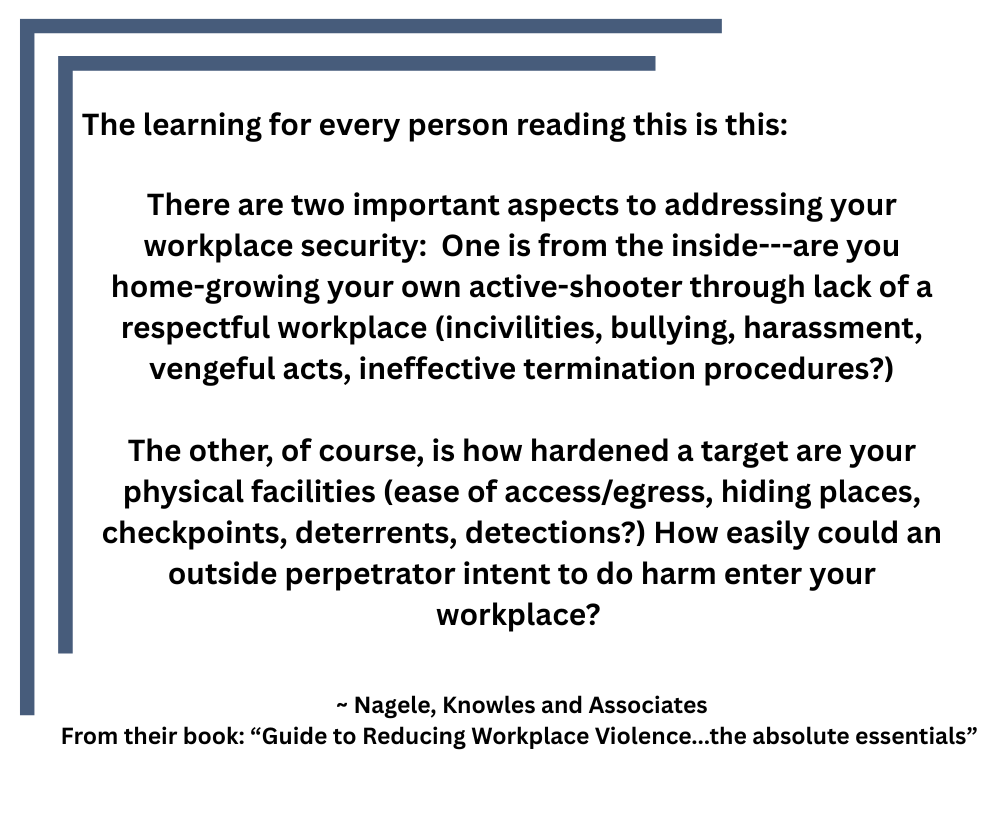

About 43% of the incidents in this report are caused by people who do not have a relationship with the organization, which means we must always have a high level of situational awareness since we do not know where or when the attack will occur.

About 29% of the fatalities are by someone who has been terminated. This raises a bunch of questions about how your organization works with those who are terminated. This is a traumatic event for the person. Does your organization just dump the person onto the street with no help for them as they go forward with their lives? This is very scary for the person, and they may lash out at someone in the organization and kill them.

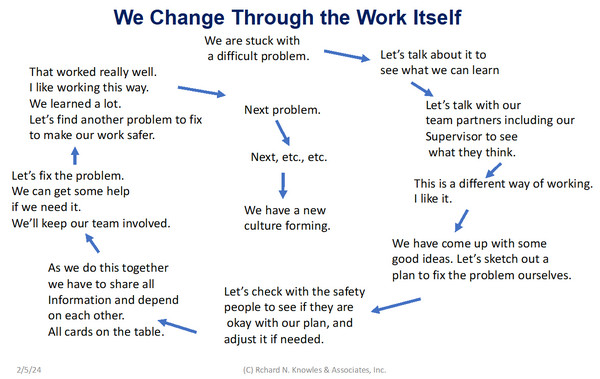

Some Things to Think About…

- Does your organization provide some assistance for the person to help them to make this tough transition in their lives?

- Is there any severance pay?

- Do they really understand why they were terminated?

- How do they talk with their loved ones?

- Where do they go for medical coverage assistance?

- Do they have any special needs situations at home that will be difficult to handle?

- Where is the local unemployment assistance office located?

- Will your HR people help them fill out the necessary forms?

- Will you help them get a job at a place that is more suitable for them?

- Do you refer them to a hiring agency?

- Does your organization help with family counseling organizations to which you can refer them?

In some termination situations, the threat of violence can be quite immediate. Has your organization ever talked with the local police about this possibility and how to handle it? After several terminations of people from my plant, I would get around-the-clock protection from an off-duty police officer for a few days. These are stressful situations, and we need to be properly prepared. Each situation is different so the specific things you will do will be different from one place to another.

Some Guidelines for Workplace Violence

In these difficult situations, treat people with respect and care. Listen to them and try to understand their perspective and thinking, if you can. Put yourself into their shoes and think about what is happening to them. Talk with them about the transition and the problems they may face. Offer guidance about getting healthcare coverage, seeking new employment, and maybe new job training.

Hopefully, none of you will face these situations, but in case you do, some up-front thinking and conversations in your organization would be very helpful.