Safety Challenges are Still With Us!

In times like this, when the business and production activities are ramping up, there is a real danger that safety problems will show up. Any time the level of activity changes, up or down, is a time of danger.

In times like this, when the business and production activities are ramping up, there is a real danger that safety problems will show up. Any time the level of activity changes, up or down, is a time of danger.

Talk with the people about these issues as well. Every day have tool box or pre-start meetings to talk about the challenges for the day. Ask the people what their biggest hazards are for the day and what they are doing to prepare for them and to protect themselves and the processes. At the end of the day, have another safety conversation and reflect on the day and whether the things that they talked about at the start really helped. Talk about the surprise for the day and how they overcame these challenges.

Keep the safety dialogue going. One of the best ways to show that you really care about the people is to work hard on the safety front. Go into the workplaces, listen, talk together, and build collaboration, helping everyone to work towards a healthy, safe and profitable business.

For example, the workers on the Deepwater Horizon drilling platform received good recognition for outstanding occupational safety performance (the slips, trips and falls sorts of incidents) just a day or two before the explosion on April 20, 2010, that killed 11 people and injured 17 others. The pressures from top management to get into production led to failures of their process safety management (PSM) systems and processes. Communications were limited because management did not want to hear of more problems; they were driving the production schedule. The fine occupational safety performance masked the PSM deficiencies which are more subtle and invisible to upper managers, unless they are keenly aware of the needs for excellent PSM.

For example, the workers on the Deepwater Horizon drilling platform received good recognition for outstanding occupational safety performance (the slips, trips and falls sorts of incidents) just a day or two before the explosion on April 20, 2010, that killed 11 people and injured 17 others. The pressures from top management to get into production led to failures of their process safety management (PSM) systems and processes. Communications were limited because management did not want to hear of more problems; they were driving the production schedule. The fine occupational safety performance masked the PSM deficiencies which are more subtle and invisible to upper managers, unless they are keenly aware of the needs for excellent PSM. Now we have another example with the mess at Boeing and the 737 Max crashes. Top management was feeling the pressures for market share from Airbus and putting terrific pressures on cost reduction and faster production.

Now we have another example with the mess at Boeing and the 737 Max crashes. Top management was feeling the pressures for market share from Airbus and putting terrific pressures on cost reduction and faster production. This is quite attainable with authentic, courageous leaders who take a stand that this is the sort of place they want to lead. The knowledge and technology are available and broadly known by lots of people so I want to share my own experiences.

This is quite attainable with authentic, courageous leaders who take a stand that this is the sort of place they want to lead. The knowledge and technology are available and broadly known by lots of people so I want to share my own experiences. This all began with my determination to work on improving respect, civility and safety. As I built credibility and trust with everyone, people began to make improvements in many other areas. Everything got better.

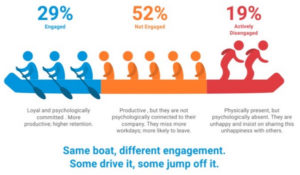

This all began with my determination to work on improving respect, civility and safety. As I built credibility and trust with everyone, people began to make improvements in many other areas. Everything got better. In 2017, Gallup, Inc. published their “State of the Global Workplace,” looking at the levels of productivity around the world. They were concerned about the decline in productivity and wanted to develop a better picture of the situation. High productivity is a key to having a good quality of life, and this relates to how involved people are in their work. They found that worldwide, only about 15% of the people are highly involved. This varies from country to country with the highest levels of involvement in the USA and Canada at 31%. Those businesses in the top quartile of employee involvement in their global study are 21% more profitable and 17% more productive. They also have 70% fewer safety incidents, 40% fewer quality incidents, 41% lower absenteeism, and 59% lower turnover. The positive impact of employees being highly involved is huge.

In 2017, Gallup, Inc. published their “State of the Global Workplace,” looking at the levels of productivity around the world. They were concerned about the decline in productivity and wanted to develop a better picture of the situation. High productivity is a key to having a good quality of life, and this relates to how involved people are in their work. They found that worldwide, only about 15% of the people are highly involved. This varies from country to country with the highest levels of involvement in the USA and Canada at 31%. Those businesses in the top quartile of employee involvement in their global study are 21% more profitable and 17% more productive. They also have 70% fewer safety incidents, 40% fewer quality incidents, 41% lower absenteeism, and 59% lower turnover. The positive impact of employees being highly involved is huge. Most people in management positions focus on systems and processes like running a payroll or production line. They want reliability, predictability, control, and stability, which are important for much of the business. But when they apply this approach to people, things go downhill. This approach results in 71% of the people globally being unengaged and 19% being actively disengaged. Morale, safety and engagement are a mess. Managers engage in managership, and this will not solve the problem of building higher levels of engagement.

Most people in management positions focus on systems and processes like running a payroll or production line. They want reliability, predictability, control, and stability, which are important for much of the business. But when they apply this approach to people, things go downhill. This approach results in 71% of the people globally being unengaged and 19% being actively disengaged. Morale, safety and engagement are a mess. Managers engage in managership, and this will not solve the problem of building higher levels of engagement.

The way in which we think about and work with all the people is a key shift that is needed.Leading thinkers like Eric Hollnagel, Tom McDaniel, Beth Lay, Carl Stent, and Ron Gantt are searching for better, more effective ways of engaging with everyone to build on the good things people are doing.

The way in which we think about and work with all the people is a key shift that is needed.Leading thinkers like Eric Hollnagel, Tom McDaniel, Beth Lay, Carl Stent, and Ron Gantt are searching for better, more effective ways of engaging with everyone to build on the good things people are doing. It is a problem across society in general and a big safety and HR problem in our organizations. In 2017, it is estimated that there were about 72,000 overdoses across the country. About 70% of businesses report that they have been impacted by this terrible problem. The National Safety Council reports that there are problems with poor prescription drug use, higher absenteeism, injuries, and accidents resulting from overdoses.

It is a problem across society in general and a big safety and HR problem in our organizations. In 2017, it is estimated that there were about 72,000 overdoses across the country. About 70% of businesses report that they have been impacted by this terrible problem. The National Safety Council reports that there are problems with poor prescription drug use, higher absenteeism, injuries, and accidents resulting from overdoses. Next, you need to reach out to the people with respect and offer to help them. Many people with drug problems believe no one cares, so reaching out to help would be a step forward.

Next, you need to reach out to the people with respect and offer to help them. Many people with drug problems believe no one cares, so reaching out to help would be a step forward.