A New Safety Leadership Paradigm is Needed

This is a question I have been thinking about for quite some time. There are lots of good people working to improve our safety performance, yet the numbers hardly change from one year to the next. In reading Kuhn’s “The Structure of Scientific Revolutions” (1962), the idea of a paradigm shift comes to mind. A paradigm shift is when the basic concepts and practices of a particular area of study need to change. Perhaps a change in the way we approach total safety performance is needed; we need a safety leadership paradigm change!

Background: Our Current Safety Management Paradigm

For years we have looked at the structure of organizations as if they are machines focusing on things, equipment and tools, even seeing people (the employees) as if they were merely interchangeable parts of the machine. Since the advent of OSHA, this approach has really improved the total safety performance of most organizations, yet across our industry we now seem to be stuck. The underlying pattern is one driven by fear of failure and punishment. The energy is driven down from the top with little feedback. Most people resist processes of power and change being imposed on them. Information flow is restricted to a “need to know” basis. Perhaps we have improved total safety performance about as much as we can using this approach. I know from my own experience as a plant manager in leading this way, that improving and sustaining the safety performance is slow and difficult.

Partner-Centered Leadership: A New Safety Leadership Paradigm

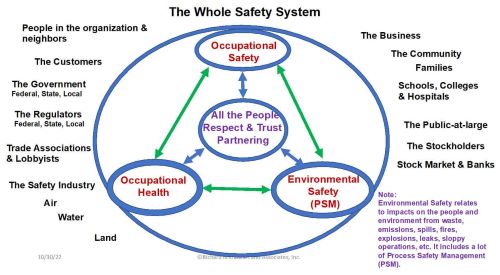

I spent a lot of my time as the plant manager studying how and why organizations work or not. The ideas coming out of the new insights about complexity, chaos, and complex adaptive systems offered a different way to lead. I learned to see organizations as if they are living systems and a new paradigm formed. I saw people as caring and partners in our work together. The relationships with and among the people became the most important feature of our work. People want to be respected. They want to be heard. They have ideas they want to share. They know more about their work specific work than I did as the Plant Manager.

We shared information abundantly providing almost constant feedback to each other. We co-created our future using a guided conversational process called “The Process Enneagram” (see my YouTube videos to learn about this process). We learned Self-Organizing Leadership and developed the Partner-Centered Leadership approach1. People took responsibility for their work and new ideas constantly emerged as we talked together. Change happened as we learned to work together in new ways finding the results of work getting better and better. The collective intelligence of the people blossomed.

The people (everyone) and I had to learn to work this way as we worked together. We gradually found that the safety performance (TRIFR down 97% in 4 years) and everything else improved. As we learned about Self-Organizing Leadership, we realized that as people self-organized around their work that the system needed to be held together with a container that allowed the flow of information and energy but did not overcontrol the system. I called this container “The Bowl.” Some people talk about needing “guide rails,” which is also a useful idea.

A Comparison of the Managing and Partner-Centered Leadership

I wrote a paper for Professional Safety in 2022 about our work at our plant and comparing the effectiveness of the Managing and Partner-Centered Leadership processes2. It clearly showed the superiority of the Partner-Centered Leadership process.

The Partner-Centered Leadership process may very well be the new paradigm that is needed to greatly reduce the number of people being killed (~5,200/year) and injured (~2,400,000 people/year).

Please seriously consider this and let’s work to get a lot better. This is not just trying harder; it is really about doing things differently and more effectively.