I have been trying to understand why the number of people getting hurt and killed at work is not getting better.

According to the Bureau of Labor Statistics, since 2017 the number of people being killed at work is averaging about 5,130 a year, with no sign of improvement and the injury frequency rate is stuck at about 2.7 for that period.

There is a lot of effort being put into trying to improve safety with the global effort totaling about $20,000,000,000 being spent for services, regulation, equipment, trade associations, etc. This is a huge industry; I call it “Big Safety.” Why isn’t Big Safety making more progress in reducing the number of people getting hurt and killed? These are real people and their families that are suffering so much.

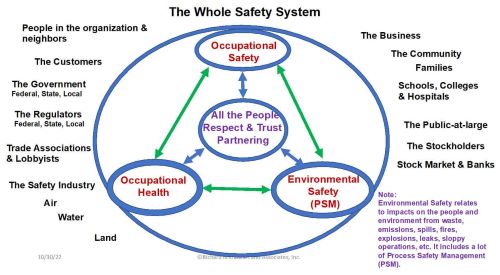

I have been getting some help from Kerry Turner and Marc Pierson in looking at the safety work from a systems perspective. The safety system is huge with many factors at play. The systems approach is helpful in being able to see the whole system, the various components, how they interact, find key points where changes can be made.

One thing that I have seen is that injuries and incidents are local events, and it is hard for Big Safety to know what really happened in detail. What it offers often does not fit quite right and comes across to the people as “the Flavor of the Month.” The people doing the work have little confidence in what the offerings provide so they often do not stick very well.

Another thing that I have noticed is that the consultants coming out of Big Safety often are seen as “experts” and come into the organization to fix the people rather than teaching the people how to solve their own problems. This weakens the people and tends to disempower them. This is a lot like Big Government coming into a local community to fix a problem when they do not know the people or much about the real nature of the problem they are coming in to fix.

In studying the Safety System, it becomes obvious that trust is a central feature that is often missing when Big Safety comes into the organization. There has been a lot written about the importance of trust, and in using a systems approach, trust really emerges as the central feature that needs to be in place before much progress in improving safety performance can take place. Real progress requires the energy, creativity and commitment of the people doing the work. This is a gift that people will give if they have trust in the other people and feel safe in opening up to meet the safety challenges.

A Suggested Approach to Building Trust

Perhaps when a consultant comes into an organization to work on a safety issue, they come into the organization 2-3 days before their planned work begins and walk into the facility among the people to get acquainted with them. Talk with the people, listen to their concerns, and discover what the real problems are that are causing the need for improved performance. Talk about their work with them and find out what they need so they can work more safely and effectively.

Open yourself up to their questions and concerns about you. Creating a safe space where they can talk with you is an important step in building trust with the people. Then the consultant needs to reflect on all that was learned and see how their knowledge and skills can be used to help the people to solve their problems. Don’t try to solve their problems for them or fix them. Rather teach them how to solve their own problems.

I have found that this approach works very well in helping to get to know the people, the issues, and to begin to build trust.